CT Hotel

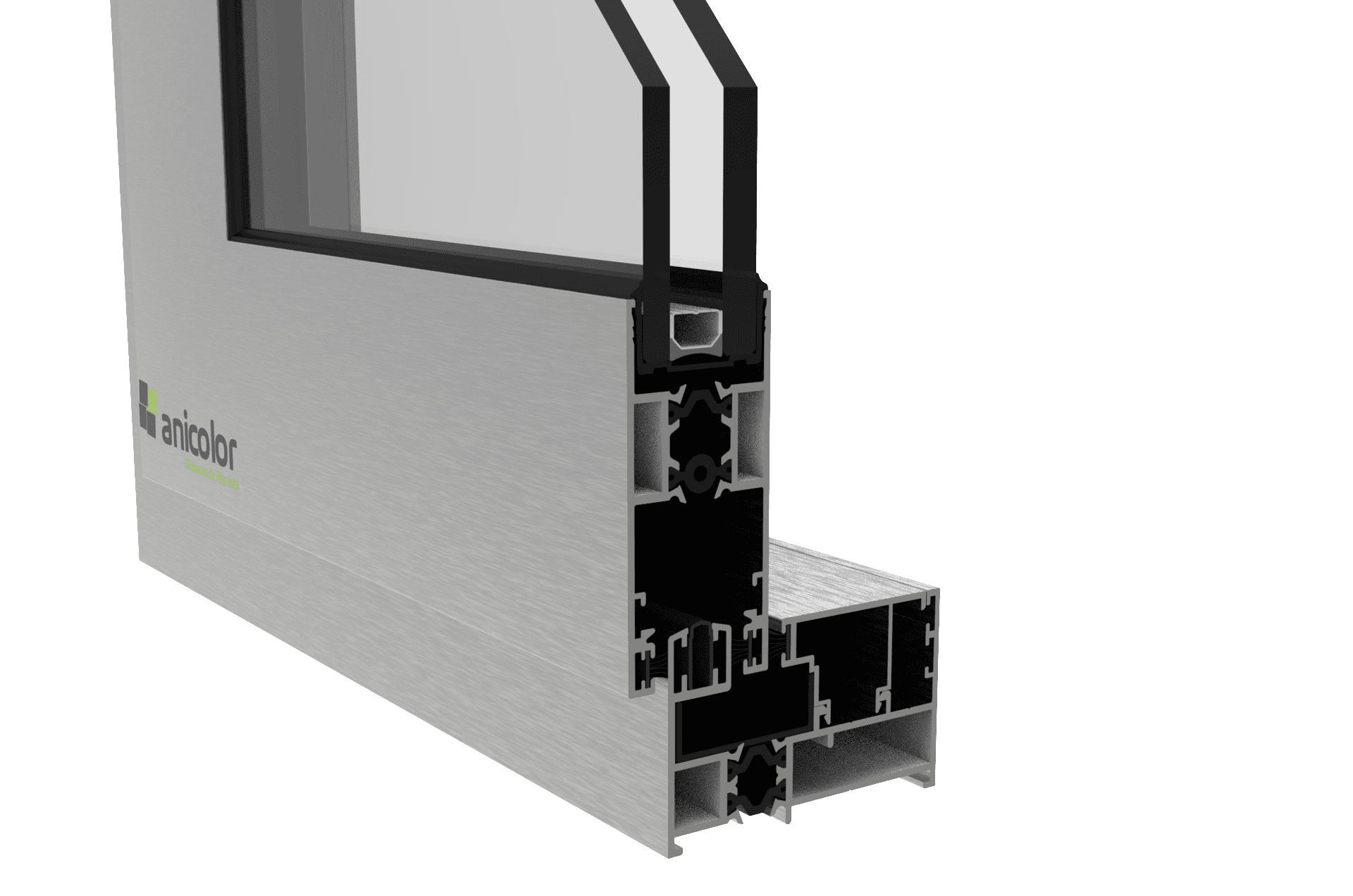

70mm

System Features

Aluminium system with thermal break for sliding openings.

The CT - Hotel system was designed to meet the requirements of a sliding window solution that is easy to use, practical, and delivers exceptional performance. With configurations of 1 or 2 sashes, it establishes an efficient performance standard from an energy, comfort, affordability, and sustainability perspective.

The CT - Hotel system allows the use of insulating double glazing to meet the thermal and acoustic insulation requirements in accordance with Directive No. 2010/31/EU.

The aluminium profiles with thermal insulation provide excellent comfort and energy-saving performance, complying with the requirements of Decree-Law No. 194/2015 and Ordinance 379-A/2015.

Aluminium Profiles

• Aluminium profiles are extruded from alloy 6060 for architecture, according to standard NP EN 12020-02;

• Thermal break achieved using omega-type polyamide insulating bars of 14.8 mm and 24 mm, reinforced with 25% fibreglass;

• Average aluminium profile thickness: 1.5 mm.

Fixed Frames

• Perimeter fixed frame section: 70 mm and 86 mm with triple chamber;

• Fixed frames with thermal break using 14.8 mm omega-type polyamide bars;

• Fixed frames with double quick-fit brackets and alignment brackets for more efficient mitered assembly;

• Fixed frames with interior clip for inner trim applications of 30, 50, 65 or 80 mm;

• Bottom sliding guide profile in stainless steel 304 or polyamide to avoid wear;

• Allows connection to AJi or AJi Canal 16 thermal break casement systems.

Movable Frames

• Perimeter section of movable frames: 33.1 mm for mitered assembly;

• Glazing thickness from 18 mm to 26 mm;

• Movable frames with straight or curved lines, with or without glazing beads;

• Sealing ensured by TPE gaskets and/or Sin-Feal type brush seals.

• Movable frame section: 33 mm with triple chamber;

• Movable frame with thermal break using 14.8 mm or 24 mm omega-type polyamide bars;

• Movable frame with double quick-fit brackets and alignment brackets for more efficient mitered assembly;

• Minimalist central mullions with 40 mm width;

• Sealing ensured by Sin-Feal type brush seals.

Sizing and Operability

• Minimum – maximum sash dimensions: 300 mm – 2000 mm (W); 350 mm – 2600 mm (H);

• Maximum weight for sliding windows or patio doors: up to 150 kg;

• Opening options: 1 or 2 sashes with fixed side panels;

• Glazing thickness for opening sash: 20 mm to 26 mm; in fixed area: 18 mm to 22 mm;

• Oscillating double bearing with adjustment;

• Stainless steel needle bearings with tempered and ground axle, replaceable without sash removal;

• Outer bearing support with cataphoresis treatment (anti-corrosive);

• Opening with side lock or multipoint hardware;

• Multipoint stainless steel hardware with one or multiple locking points, adjustable, and including anti-misoperation device for better efficiency and safety.

Performance • System to be certified by a notified laboratory for Initial Type Testing (ITT) in accordance with product standard EN 14351-1:2006+A2:2016 for CE marking purposes.

Performance classes achieved for the CT system – window type:

• Air permeability: Class 4 (test standards EN 10207 and EN 1026)

• Water tightness: Class 7A (test standards EN 10208 and EN 1027)

• Wind resistance: Class C5 (test standards EN 12210 and EN 12211)

Performance classes achieved for the CT system – door type:

• Air permeability: Class 4 (test standards EN 10207 and EN 1026)

• Water tightness: Class 7A (test standards EN 10208 and EN 1027)

• Wind resistance: Class B2 (test standards EN 12210 and EN 12211)

Thermal transmittance coefficient for 1 sash with side fixed panel, CT - Hotel system, 3.0 m x 2.20 m with double glazing Ug = 0.9 W/m²K and Warm Edge spacer:

• Uw = 1.47 W/m²K

Acoustic attenuation coefficient for 1 sash with side fixed panel using laminated double glazing 44.2 Stratophone + cx10 + Planibel Clearlite 4 mm:

• Rw (C; Ctr) = 34 dB (–2; –6)

Acoustic attenuation coefficient for 2 sashes using 33.2 silence /10/4 and 33.2 silence /8/4 glazing:

• Rw (C; Ctr) = 38 dB (–1; –4)

Application zones according to REH and RECS regulations (based on Ug value): I1, I2, I3, V1, V2, V3;